Maximising Yacht & Marine Container Storage: Innovative Racking Solutions for Seafaring Spaces

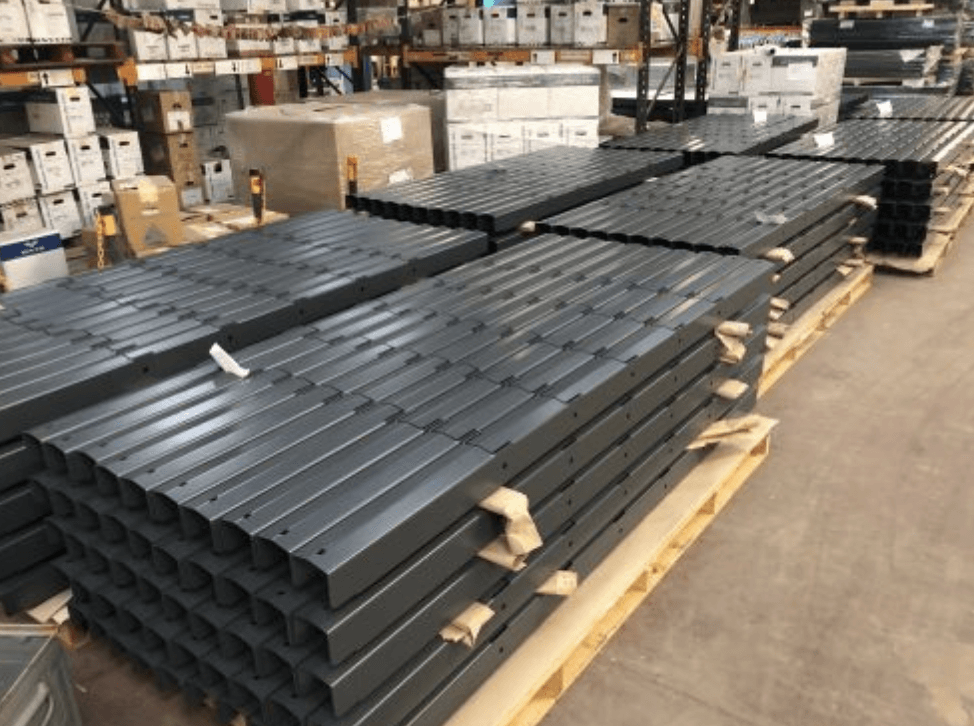

Yacht & Marine Container Storage

If there’s one thing everyone in the marine world agrees on, it’s that space is a luxury. Whether you’re running a superyacht, managing a dockside workshop, or operating offshore equipment containers, every inch has to earn its keep.

That’s why efficient storage isn’t just a convenience — it’s a necessity. Tools, spare parts, provisions, and safety gear all need to be accessible, secure, and protected from harsh marine conditions.

The problem? Standard shelving systems often fall short. They corrode, loosen, or simply don’t make the best use of tight, uneven spaces.

That’s where modular container racking systems, like those from Container Rack, come into their own. Designed to fit perfectly inside ISO shipping containers, they offer a smart, reliable way to bring order to even the smallest onboard or dockside spaces.

The Challenge of Marine Storage

If you’ve ever worked in a marine environment, you’ll know the unique challenges it brings. Salt air, humidity, and constant motion can wreak havoc on traditional storage solutions.

On yachts and in ports, containers are often used as workshops, supply stores, or maintenance stations — but without a structured racking system, they can quickly turn into chaos. Boxes get stacked in unsafe piles, tools go missing, and valuable space goes to waste.

That’s not just inconvenient — it’s inefficient. In a busy marine operation, wasted space can mean wasted time, and wasted time can mean lost revenue.

Why Container Racking Works So Well in Marine Settings

What makes container racking systems so effective in these environments is their simplicity and strength. Container Rack’s systems are built from galvanised steel, which naturally resists corrosion and moisture — perfect for dockside or offshore use. Our racking also fix directly to a container’s existing lashing points, meaning there’s no drilling, welding, or permanent alteration to the structure. You can install a complete setup in under an hour using just basic tools.

That’s especially valuable when working in confined or sensitive areas like a yacht’s service container, where flexibility and cleanliness are essential.Because the system is modular, it can easily be reconfigured as your needs change — for example, switching from spare parts storage to dive gear, or from provisions to maintenance tools.

Real-World Uses: From Superyachts to Shore Facilities

We’ve seen container racking used in all sorts of creative ways across the marine industry.

On superyachts, it’s often installed in technical containers used for maintenance equipment or water toys — think jet skis, inflatables, or dive gear. The racking keeps everything neat, easy to access, and protected from movement during transit.

In boatyards and marinas, operators use it to create efficient storage hubs for spare parts, paint supplies, and tools. Because the system connects directly to the container frame, it remains rock-solid even in rough conditions or high humidity. And, offshore, container racking is often fitted into engineering or logistics containers used on oil rigs or ships. These setups require strength and safety, and the heavy-duty racking handles both with ease.

Durability in Harsh Conditions

There’s no avoiding it — the sea is tough on equipment. That’s why material choice matters.

Container Rack’s galvanised steel systems are specifically designed to handle fluctuating temperatures and salt-laden air. Unlike untreated metal shelving, they won’t rust, warp, or weaken over time.

Even better, if your container needs to be moved between locations — from dock to vessel, or from shipyard to offshore platform — the racking travels safely with it. The bolt-free design means no loose fixtures and no need for reinstallation every time you relocate.

Making the Most of Limited Space

Yacht and marine storage often comes down to creative thinking. When space is tight, vertical organisation is your best friend.Racking lets you take advantage of your container’s full height, transforming wasted wall space into structured storage. Small parts, spares, and tools can be organised in labelled boxes on adjustable shelves, while bulkier items sit securely on lower levels.

The result? A container that feels twice as large — without actually increasing its footprint. For yacht crews, that means smoother operations and faster access to the equipment they need. For marinas and service companies, it means better workflow and professional presentation.

Why Modular Design Makes a Difference

Marine operations are never static. Needs evolve — sometimes week by week. That’s what makes modular racking such a smart choice. You can add, remove, or reconfigure sections as your storage requirements change. Maybe you start with a standard setup for supplies and later decide to expand into heavier-duty storage for mechanical equipment — the same racking framework can adapt. That flexibility means your investment keeps working for you, no matter how your operation grows or shifts.

In the marine world, smart storage isn’t just about keeping things tidy — it’s about safety, efficiency, and long-term durability.

With Container Rack’s modular container racking systems, you can transform a basic storage container into a well-organised, corrosion-resistant workspace that stands up to the demands of life at sea.

Whether you’re managing a yacht’s technical container, a marina’s maintenance hub, or an offshore supply unit, these systems help you maximise space, minimise clutter, and stay in control — even when conditions are anything but calm.

Ready to make the most of your marine storage?

Explore our full range of racking systems and try the

Build-Your-Own Configurator to design a setup that fits your container — and your operation — perfectly.

Would you like me to optimise this blog next with internal linking suggestions and keyword metadata (title tag + meta description + target keywords list) so it’s upload-ready for the Container Rack website?