Creative Storage Solutions for Tradespeople: Turning Containers into Efficient Tool & Material Hubs

Discover smart storage solutions for tradespeople

For many tradespeople, a shipping container provides the ideal balance of security, durability, and space. Whether positioned on a construction site, kept in a depot, or used as a mobile storage unit, containers offer a reliable way to keep tools and materials protected.

However, without a structured approach to organisation, even a large container can become cluttered and inefficient. Time is often lost searching for specific tools, materials become difficult to access, and valuable space goes underused.

With the right storage strategy, a shipping container can be more than just a box for storing equipment — it can function as a well-organised, professional hub that supports smoother daily operations and faster workflows.

Creating a Dedicated Space for Everyday Tools

One of the biggest challenges tradespeople face is keeping frequently used tools accessible. A clear organisation plan helps overcome this. Establishing a dedicated zone for essential tools near the front of the container ensures quick access at the start of the day and reduces unnecessary movement inside the unit.

Tools that are used daily — drills, hand tools, fixings, or battery packs — benefit from being stored at a comfortable height and in areas where they can be returned easily. This prevents them from being buried under heavier items and helps maintain a consistent workflow.

Organising Materials for Efficiency and Safety

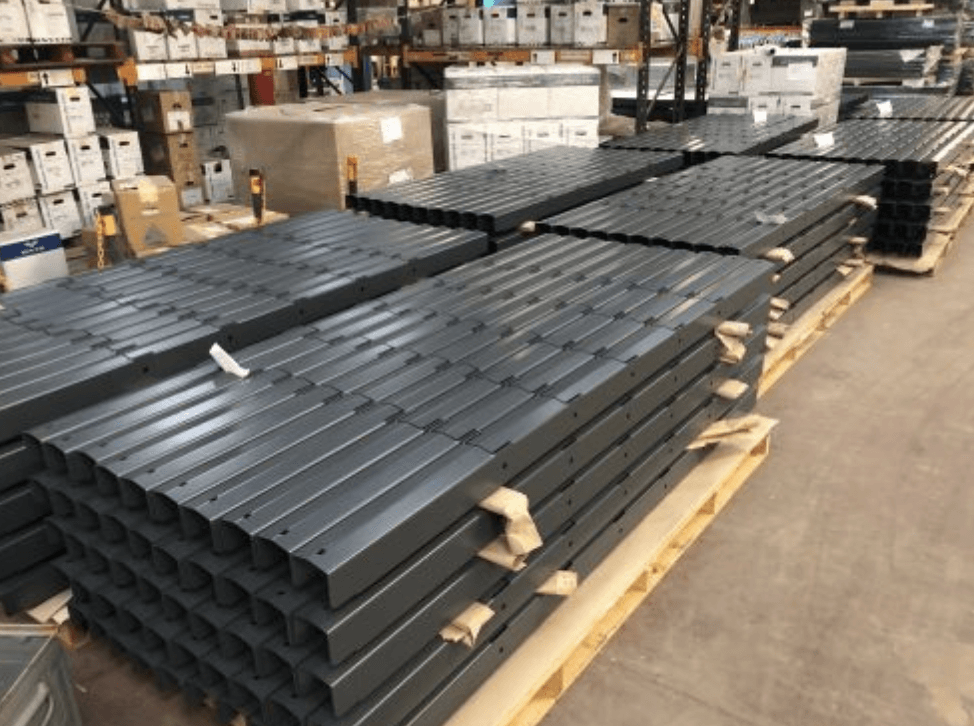

Trades often involve handling large volumes of materials such as timber, pipes, fittings, cables, and hardware. If left unorganised, these items can quickly take up valuable floor space and create trip hazards.

A structured shelving system allows tradespeople to separate materials by type, size, or project. This not only improves efficiency when gathering supplies but also reduces the risk of damage or loss. Keeping the floor clear enhances safety and allows heavier materials to be moved with greater ease.

Using Vertical Storage to Maximise Capacity

Shipping containers offer generous height, yet this space is often underutilised. Vertical storage plays a significant role in increasing capacity without expanding the container footprint. Installing strong, container-specific racking enables items to be stored across multiple levels, freeing the floor for larger equipment. This approach is particularly effective for trades that require a wide range of small or medium-sized tools and components. By organising upwards rather than outwards, the container becomes significantly more efficient.

Maintaining Order Through Clear Zoning

Tradespeople often work across several projects simultaneously, each requiring different tools and materials. Establishing clear zones within the container helps maintain order and reduces time spent searching for equipment.

For example, one section can be reserved for power tools, another for fixings or consumables, and a third for site equipment such as PPE or ladders. These internal “departments” help create consistency, even when multiple people access the container throughout the day.

Improving Workflow with Thoughtful Layout Planning

Effective container design is not only about storage — it also needs to support movement and workflow. A central walkway provides safe access to all items and ensures that equipment is retrieved without excessive lifting or manoeuvring.

Positioning heavier equipment at waist or floor height improves manual handling safety. Items that are used less frequently can be placed deeper inside the container or higher on shelves, preserving prime space for tools used daily.

Making Use of Durable, Long-Lasting Fixtures

The demanding environments many tradespeople work in—construction sites, workshops, marine settings—require storage solutions that can withstand heavy use. Galvanised steel racking is particularly suited to these conditions due to its strength and resistance to rust or corrosion.

Because container-specific racking connects securely to the container’s lashing points, it offers stability even in changing weather or high-traffic environments. This reliability helps keep tools safe, reduces wear and tear, and ensures the container remains functional for years to come.

Adapting the Container as Your Business Evolves

One of the advantages of modular racking is its adaptability. As a business grows or changes direction, storage requirements naturally shift. The ability to adjust shelf heights, add extensions, or redesign the internal layout allows tradespeople to keep their container aligned with current needs without investing in new storage units.

Whether transitioning from general building work to specialist trades, expanding your team, or simply acquiring more tools, flexible shelving supports long-term efficiency.

Conclusion

Shipping containers offer tradespeople an excellent foundation for secure, practical storage. With the right organisational strategies and a well-planned layout, a container can function as a streamlined, professional hub that enhances day-to-day workflows and protects valuable tools and materials.

Container Rack provides robust, galvanised racking systems designed specifically for container environments, making it easy to create a well-structured space that meets the demands of modern trade work.

Ready to build a more organised, efficient tool hub?

Start designing your ideal setup using our

Build-Your-Own Configurator and tailor your container to your exact requirements.