Heavy-Duty vs Standard-Duty Container Racks: A Complete Buying Guide for UK Businesses

Heavy Duty Vs Standard Duty

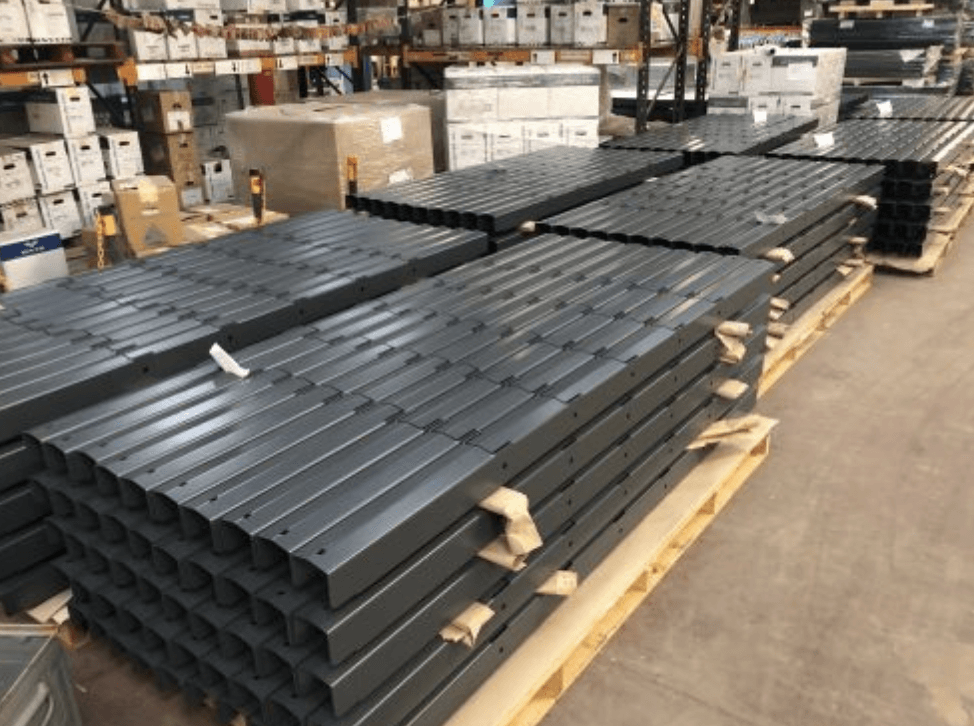

In the world of self-storage, space is profit. Every inch you can make usable adds value — for your customers and your business. Whether you manage a storage park filled with shipping containers or rent out individual units, the right racking system can completely transform how efficiently that space is used.

But with multiple types of container shelving systems on the market, it’s not always clear which one best fits your needs. Do you prioritise strength, cost, or flexibility? Should you choose standard-duty or heavy-duty racking?

In this guide, we’ll break down everything you need to know about choosing the right container racking system for self-storage. You’ll also see how Container Rack’s modular, bolt-free systems make it simple to design, install, and adapt your layout for any purpose.

1. Understand Your Container’s Layout and Usage

Before you choose a system, start by understanding how each container is used.

- Single-tenant containers: If one customer rents the whole container, shelving on one or both sides is usually ideal. This keeps the middle area free for larger items.

- Multi-tenant containers: When containers are divided into smaller spaces, modular racking that can be easily reconfigured or removed works best.

- High-turnover containers: For units accessed frequently, quick-fit, adjustable shelving is a must.

It’s also important to measure the interior height, width, and door clearance carefully. Note where the lashing points are — Container Rack’s systems are designed to attach directly to these points, meaning no drilling or permanent alterations are required.

2. Choose Between Standard-Duty and Heavy-Duty Racking

The next step is deciding on the load capacity that suits your storage needs. Container Rack offers two main options:

Standard-Duty Racking:

- Upright load capacity: 300 kg

- Shelf load capacity: 100 kg

- Ideal for: boxes, personal storage, small business use, tools, household items.

- Benefits: lightweight, affordable, and perfect for general self-storage units.

Heavy-Duty Racking:

- Upright load capacity: 450 kg

- Shelf load capacity: 200 kg

- Ideal for: commercial storage, machinery, trade equipment, and industrial applications.

- Benefits: superior strength and stability for heavier or awkward items.

For most self-storage sites, standard-duty racking is the best balance between strength and cost. But if you cater to industrial or trade clients, heavy-duty shelving offers the extra resilience you’ll need.

3. Prioritise Modular, Bolt-Free Assembly

Traditional shelving often needs drilling, bolting, or welding — not ideal inside a shipping container where speed and flexibility matter.

Container Rack’s bolt-free modular design connects directly to existing lashing points, allowing for quick installation without damaging the container.

That means:

- No drilling or cutting.

- Simple assembly with basic hand tools.

- Fast setup and easy removal if you repurpose or relocate containers.

A single person can usually install a system in under an hour, making it one of the most efficient racking setups available.

4. Maximise Vertical and Horizontal Space

Efficient space planning is the key to profitability in container storage.

Here are some layout tips to help you make the most of every square inch:

- Go vertical: Use three- or four-tier shelving to utilise container height.

- Balance the load: Keep heavy or bulky items on lower shelves for safety.

- Two-side setups: For 20ft or 40ft containers, install shelving along both walls, leaving a central aisle for access.

- Customise spacing: Adjust shelf heights to fit different item sizes or seasonal storage needs.

A well-organised layout not only increases capacity but also improves safety and makes each unit more attractive to customers.

5. Consider Durability and Corrosion Resistance

Shipping containers face all sorts of weather — temperature swings, condensation, humidity, and even salt air in coastal areas. That’s why racking systems need to be tough.

Container Rack’s systems are made from galvanised steel, providing long-term resistance to rust and corrosion. This ensures your setup remains strong, safe, and maintenance-free, even in exposed outdoor storage environments.

6. Customise with the Build-Your-Own Configurator

If you’re unsure where to start, the Build-Your-Own Configurator on the Container Rack website makes it simple.

You can:

- Choose container size (10ft, 20ft, 40ft, etc.)

- Pick between standard-duty or heavy-duty racking

- Visualise your layout before placing an order

It’s quick, accurate, and ideal for both one-off installations and large-scale storage site setups.

Choosing the right container racking system for your self-storage facility doesn’t have to be complicated. By understanding your container’s layout, intended use, and required load capacity, you can design a system that’s safe, efficient, and built to last.

At Container Rack, we specialise in modular, bolt-free racking systems that work with your containers — not against them. From single units to full-site installations, our systems make storage simpler, safer, and more profitable.

Ready to get started?

Try our

Build-Your-Own Configurator today and create the perfect container racking layout for your self-storage business.