How Much Weight Can Container Shelving Hold? Understanding Load Limits and Safe Storage Practices

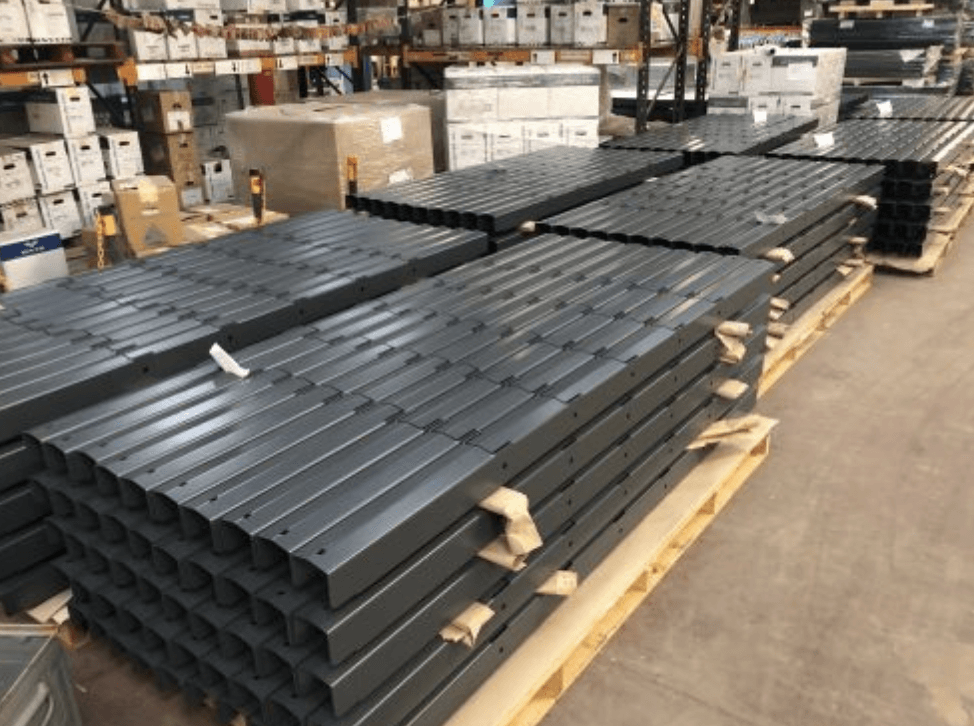

Shipping containers are widely used for storage across industries such as construction, logistics, agriculture, self-storage, and marine operations. Their strength and durability make them ideal for securing tools, equipment, and materials. However, the performance of the shelving inside the container plays a crucial role in overall safety and efficiency.

Understanding how much weight your container racking can hold is essential. Exceeding load limits can lead to damaged equipment, unstable shelving, and avoidable safety risks. This guide outlines the key factors affecting weight capacity, explains the difference between standard-duty and heavy-duty shelving, and highlights best practices for safe storage.

Load Capacity: The Key Performance Indicator

The most important measure of a shelving system’s capability is its load capacity, which typically includes two values: the maximum weight each upright can support and the maximum weight permitted per shelf level. These figures determine how much equipment or material the shelving can safely accommodate without compromising stability.

Container Rack’s systems use galvanised steel frames engineered specifically for shipping containers. Because they attach directly to the container’s existing lashing points, the load is transferred securely into the structure, creating a stable and reliable foundation.

Standard-Duty vs Heavy-Duty Capacity

Container shelving is generally available in two main strength categories. Each is designed to serve different storage requirements:

Standard-Duty Container Racking

Standard-duty shelving is suitable for general storage applications, including tools, boxed items, and light equipment. It offers:

- Upright load capacity of 300 kg

- Shelf load capacity of 100 kg

This level of strength is ideal for most domestic, small business, or self-storage environments where materials are relatively lightweight and easy to handle.

Heavy-Duty Container Racking

For industrial or commercial storage requirements, heavy-duty racking provides significantly greater capacity. Its performance includes:

- Upright load capacity of 450 kg

- Shelf load capacity of 200 kg

This makes it appropriate for storing dense equipment, machinery components, power tools, spare parts, and construction materials.

While both systems are designed for durability, the heavy-duty option offers enhanced structural rigidity for demanding storage environments.

Factors That Affect Weight Distribution

Safe storage depends not only on the shelving’s design but also on how the weight is arranged within the container. Several factors influence stability and overall performance:

- Placement of items: Heavier equipment should always be stored on the lower levels. This lowers the centre of gravity and reduces pressure on upper shelf beams.

- Even distribution: Concentrating weight in one small area can cause strain on a single upright or bracket. Spreading loads evenly maintains balance and prevents leaning.

- Container conditions: A dry, level container on firm ground ensures the shelving remains stable. Uneven floors or excessive moisture can affect structural integrity over time.

- Shelf spacing: Ensuring shelf heights match the items being stored reduces unnecessary strain and improves accessibility.

These principles help maintain long-term safety and reduce the risk of accidental damage.

Why Overloading Is a Serious Issue

Exceeding recommended load limits can lead to a number of issues, both immediate and long term. Overloading may cause shelving beams to bend, uprights to warp, or fixings to loosen. In extreme cases, it can result in partial shelf collapse.

Beyond the potential damage to stored items, such failures pose safety risks for anyone accessing the container. Overloading also shortens the lifespan of the shelving system and may lead to costly replacements or repairs. Adhering to manufacturer-specified limits is the simplest way to maintain performance and safety.

How to Ensure Your Racking Is Fit for Purpose

Selecting the right racking begins with understanding the type of items you need to store and how frequently they will be accessed. For lighter tools and general equipment, standard-duty shelving offers more than enough capacity. For environments involving dense or heavy materials, heavy-duty racking provides the necessary strength and stability.

Once installed, regularly reviewing the condition of the shelving and the placement of items helps maintain safe working conditions. A well-organised container with clear access routes and balanced load distribution remains significantly safer and more efficient.

Conclusion

The weight capacity of container shelving is a critical factor in creating a safe, effective, and long-lasting storage environment. By selecting a system with the appropriate load limits — and using it within those guidelines — you can ensure that your container remains secure, organised, and fully optimised for your operational needs.

Container Rack supplies both standard-duty and heavy-duty galvanised steel racking systems engineered specifically for shipping containers. Each system offers reliable performance and straightforward installation, allowing you to create a smart, safe storage space with confidence.